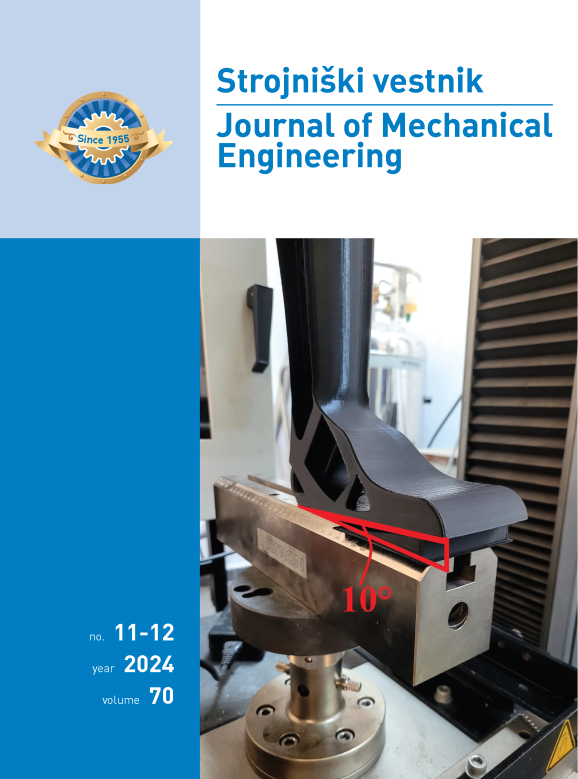

Design of 3D Printed Below-Knee Prosthetic - A Finite Element and Topology Optimization Study

DOI:

https://doi.org/10.5545/sv-jme.2024.1034Keywords:

3D printing, additive manufacturing, FEM, prosthetic design, topology optimizationAbstract

There are approximately 35 to 40 million people worldwide who require assistive devices, including prosthetics and orthoses. Most amputee patients have a lower amputation. The high cost of prosthetics, long production and delivery times, the frequent need for prosthetics in growing children and limited accessibility to prosthetics are common complaints of amputees. This study aims to design and fabricate a lightweight, high-strength, low-cost and easily accessible three dimensional (3D) printed below-knee prosthetic leg without support material to improve the quality of life of amputees. First, a flexible and jointless one-piece below-knee prosthetic leg model was designed by considering the anthropometric data of children who frequently require prosthetics. Then, using the finite element and topology optimization methods, an optimized prosthetic leg model was developed according to the results of structural analyses performed by considering the loading conditions and boundary conditions during daily activities such as standing, walking, ascending and descending stairs. Finally, the prosthetic model was modified for a support-free additive manufacturing process and a socket and heel piece were added. The designed prosthetic leg model was fabricated using the additive manufacturing method with hard thermoplastic polyurethane (TPU) material. The final prosthetic leg design achieved a safety factor of 4.14 and a weight reduction of 50.37 % compared to the solid model. In addition, a 50 % reduction in material usage and a 32 % reduction in fabrication time were achieved through topology optimization and support-free design.

Downloads

Additional Files

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 The Authors

This work is licensed under a Creative Commons Attribution 4.0 International License.